Rutgers is Partner in EQUIP-A-Pharma Program to Revolutionize U.S. Drug Manufacturing

Rutgers is one of four partners in collaboration with the Administration for Strategic Preparedness and Response (ASPR), within the U.S. Department of Health and Human Services (HHS), and the Defense Advanced Research Projects Agency (DARPA) to transform U.S. pharmaceutical manufacturing. The focus of the program is to leverage new technologies to help develop a regulatory framework able to make medicines available, wherever and whenever they are needed.

Employing advanced manufacturing technologies, AI, machine learning, and informatics, each EQUIP-A-Pharma partner will manufacture two products. These new systems could eventually produce essential medicines onsite at U.S. healthcare facilities, such as hospitals, to directly meet patient needs. Using these technologies in drug production could ultimately enhance manufacturing efficiency, lower costs, address drug shortages, speed approval timelines, and accelerate the response to national emergencies.

Rutgers is one of only four teams selected for phases 2 and 3 of the EQUIP-A-Pharma project and is the only university-led team.

“Our goal is to generate the data with new AI tools to enable a new regulatory framework for faster drug approval that gets essential drugs directly to those in need,” says Fernando Muzzio, distinguished professor in the Department of Chemical and Biochemical Engineering and director of the Center for Structured Organic Particulate Systems (C-SOPS) in the Department of Chemical and Biochemical Engineering. “Our current work builds on a previous project funded by FDA. Within EQUIP, we are turning a proof of concept system into a highly automated, GMP (good manufacturing practices)-compliant line to produce inhalable and injectable products.”

Equally important, is the project’s aim to streamline the U.S. Food and Drug Administration’s (FDA) collection and analysis of data needed to evaluate drugs that could potentially fast-track regulatory approval. “EQUIP-A-Pharma is a critical initiative in supporting a stronger domestic drug production supply chain and fostering national health security and resilience,” Muzzio explains.

A Yearlong Test

Over the next year, according to the ASPR, Rutgers – and project partners Battelle Memorial Institute and Aprecia, Bright Path Laboratories, and Mark Cuban’s Cost Plus Drug – will seek to demonstrate how their use of innovative technologies can make active pharmaceutical ingredients and specific drug medications at a point-of-care.

Each partner is responsible for boosting the manufacture of two drugs and their active pharmaceutical ingredients, to produce a total of eight sterile injectable or oral medications.

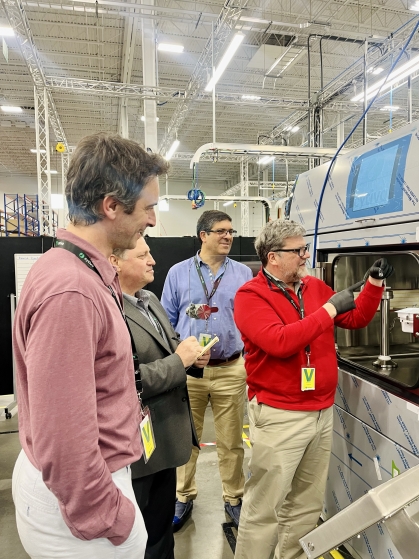

The Rutgers team, led by Muzzio, will demonstrate the production of registration batches of an anesthetic for injection, Bupivacaine HCI, and the lung and asthma inhalable medication Albuterol Sulfate. Muzzio’s team is also partnering with a Virginia Commonwealth University team led by James Ferri, professor and associate department chair of Chemical and Life Science Engineering, and CMIC CMO USA, a contract manufacturer in Cranbury, NJ. While VCU will develop the system that will synthesize both drug substances, CMIC will be responsible for the manufacturing operations in their GMP facilities.

For each project EQUIP-A-Pharma partners will submit an Abbreviated New Drug Application to the FDA within the year as a result of their leveraging government-supported development work. Partners must also develop a commercialization strategy, in support of ASPR’s and DARPA’s goal to bring the new technologies developed in the program and their applications to the market. The Rutgers team has initiated the work on this front by engaging with the Rutgers Health community and other stakeholders in New Jersey.